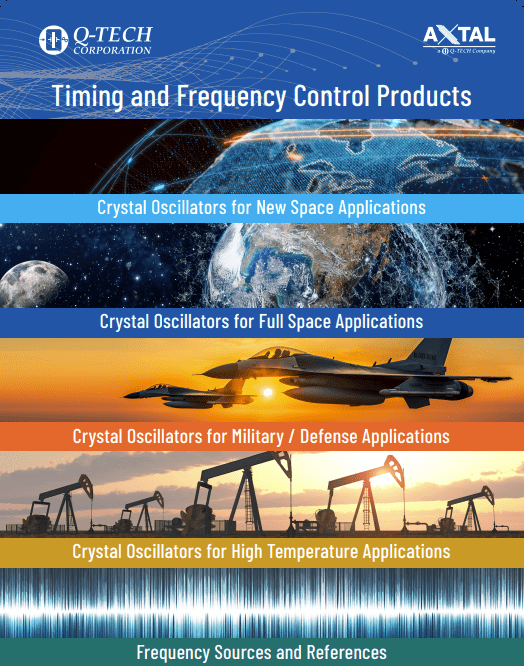

Q-Tech & Axtal solutions for Space, Military & High Temperature applications

- Home

- /

- POSTS

- /

- Technology

- /

- Q-Tech & Axtal solutions...

Q-Tech new Product Overview Booklet combines solutions for Space, Military, & High Temperature applications.

SCREENING TEST & QUALITY CONFORMANCE MIL-PRF-55310 PRODUCTS

Screening tests are standard for all MIL-PRF-55310 products. Q-Tech Corporation will customize screening and test procedures to meet your specific requirements.

Screening tests are standard for all MIL-PRF-55310 products. Q-Tech Corporation will customize screening and test procedures to meet your specific requirements.

For Space level products, Q-Tech offers Screening and Quality Conformance testing in accordance with – or superior to – MIL-PRF-55310 and MIL-PRF-38534. Our application notes describing the differences in these requirements can be found here and here.

Q-Tech Corporation also offers Screening and Quality Conformance testing in accordance with EEE-INST-0002, Level 1 (see option N).

- INTERNAL VISUAL per MIL-STD-883, Method 2017 and 2032

- STABILIZATION BAKE (Prior to Seal) per MIL-STD-883, Method 1008, Condition C (150ºC)

- TEMPERATURE CYCLING per MIL-STD-883, Method 1010, Condition C (-55ºC to 125ºC)

- CONSTANT ACCELERATION per MIL-STD-883, Method 2001, Condition A (Y1 Axis only, 5000g)

- FINE LEAK per MIL-STD-883, Method 1014, Condition A1, A1, or B1

- GROSS LEAK per MIL-STD-883, Method 1014, Condition B2, B3, or C

- PRE BURN-IN Electrical Test, Output Frequency and Waveform at nominal supply voltage, Specified Load, +23ºC ±1ºC (OPTIONAL)

- BURN-IN (Load) Energized oscillator, with nominal supply voltage and burn-in load, is tested at 125ºC for 160 or 240 hours min.

- FINAL ELECTRICAL TEST: Input Current Power, Output Frequency, Output Waveform, and Output Voltage Power are tested

QUALITY CONFORMACE INSPECTIONS (QCI)

Quality Conformance Inspections (QCI) are standard for all MIL-PRF-55310 products. Sample units are tested in accordance with Group A and Group B requirements for inspection lots.

Quality Conformance Inspections (QCI) are standard for all MIL-PRF-55310 products. Sample units are tested in accordance with Group A and Group B requirements for inspection lots.

For space level products, Q-Tech offers Screening and Quality Conformance testing in accordance with – or superior to – MIL-PRF-55310 and MIL-PRF-38534.

Our application note describing the differences in these requirements can be found here.

GROUP A

- ELECTRICAL TEST: Supply Voltage, Input Current, Output Waveform, Output Voltage Power, Rise and Fall Times, Duty Cycle, and Start-Up Time (as required)

- FREQUENCY-TEMPERATURE STABILITY: Initial Accuracy at Reference Temperature, Initial Frequency-Temperature Accuracy and Frequency-Temperature Tolerance

- FREQUENCY-VOLTAGE TOLERANCE: Output Frequency is measured when oscillator supply voltage is adjusted to its specified nominal value up to its maximum / minimum values

- OVERVOLTAGE SURVIVABILITY: Overvoltage of 20% above the maximum specified

- VISUAL AND MECHANICAL: Verify Material, Design, Construction, Workmanship, Physical Dimensions, and Marking per MIL-PRF-55310

- SOLDERABILITY TEST: per MIL-STD-202, Method 208

GROUP B

- AGING TEST: Oscillator is energized in oven for a continuous period of 30 days at 70ºC ±3ºC. The Output frequency is measured within an interval of 72 hours maximum per MIL-PRF-55310

Brochures are available for Market segments with the extensive Q-Tech catalog of oscillators.

View or download the brochures using the links in the table below.

- Q-Tech & Axtal Booklet

- Full Space Brochure

- New Space Brochure

- Military and Defense Brochure

- Specialty Products Brochure

- High Temperature Brochure

- Miniature Oscillators

- Q-Tech Web Brochure

Contact: Q-Tech Address : 6161 Chip Ave. – Cypress, CA 90630, US

Phone : (310) 836-7900

Fax : (310) 730-6440

Email: sales@q-tech.com

Web: https://q-tech.com/

| Italy Agent: DANILO LAUTA Via Guido Rossa 34, 00065 – Fiano Romano, ROME, ITALY Email: d.lauta@protec-semi.comWeb: www.microrel.com |

In Partnership with: Phone: +49 (0)89 6602923 Email: sales@protec-semi.de Web: www.protec-semi.de |

CONTACT MODULE