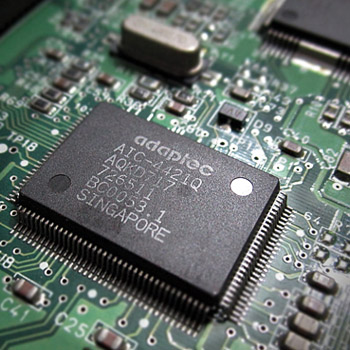

Plastic Encapsulated Microcircuit (PEM) Selection, Screening, and Qualification

Plastic encapsulated microcircuits (PEMs) have advantages over conventional hermetic packages in terms of size, weight, cost, availability, and performance.

Aerospace designers often specify PEMs to reduce cost and shorten design cycle times, although PEMs are suitable for a wide range of harsh environments. The key to realizing these advantages lies in the PEM qualification process, which upscreens commercial off-the-shelf (COTS) by lot to establish high reliability and facilitate use of these commercial devices beyond their original intent.

The advantages include:

• Greater selection of components

• Lower cost of BOM

• Smaller and thinner

• Lightweight

• Rapid procurement

PEM qualification services are part of our comprehensive approach to designing for highly demanding environments, which includes general up-screening services. The PEM Qualification flow is based on NASA Documents EEE-INST-002 and PEM-INST-001, which provides three levels of qualification dependent on application risk:

Level 1: High Reliability/Low Risk, 5+ year missions

Level 2: Low to Moderate Risk, 1-5 year missions

Level 3: High Risk, 1-2 year missions